A good example of Industrial Symbiosis

Industrial symbiosis is a B2B system approach for a more integrated industrial system and one that is more sustainable because it identifies business opportunities that optimize industrial processes and use underutilized resources (such as materials, energy, water, capacity, expertise, assets, or other by-products, etc.). This often involves finding innovative solutions that capture and exploit hitherto untapped synergies. Simple examples include the use of food waste from the catering sector to feed farm animals, or the use of non-toxic industrial waste to produce energy through incineration. Industrial Symbiosis seeks to maintain the highest (reuse) value of materials and products. One of the earliest examples of industrial symbiosis on a large scale in Europe is the Kalundborg industrial park in Denmark. It brings together an increasing number of partners that are currently exchanging 20 resources, as diverse as biomass, gypsum, and steam.

Kalundborg Industrial Symbiosis

Situated in Kalundborg, Denmark, the symbiosis is based on public-private partnerships, with exchanges of energy, water, and materials in closed loops. The vision of Kalundborg Symbiosis is to be the world’s leading industrial symbiosis with a circular approach to production. An industrial symbiosis constitutes a local partnership where, partners provide, share and reuse resources to create shared value. The purpose of industrial symbiosis is to create loops of technical or biological materials while minimizing the leakage and waste in the loops – demonstrating some key parts of a circular economy, at a local scale.

This sort of symbiosis began in Kalundborg in 1961, initially with the area’s water supply. It was not officially referred to as ‘industrial symbiosis’ until 1989, because of the participants’ philosophy: working together is just smart business. Kalundborg Symbiosis has evolved organically over the past six decades, with joint projects being created where the business case and collaboration was beneficial but ending when the business case became unfavorable.

Building a functioning industrial symbiosis is not just about working together for the sake of each other and the environment, but a continual search for a better way of doing business. To that end, Kalundborg has shown that industrial symbiosis works well as a hotbed for innovative test and demonstration projects, as well as providing great opportunities for startups. Several projects have been completed over the years, from algae production facilities to bio-ethanol production, with some projects already being implemented at scale. Several startups have also located themselves in Kalundborg to benefit from the cooperative nature and innovative mindset.

Kalundborg Symbiosis is built on core values that have made all the successful partnerships possible: trust, confidentiality, openness, equality, and cooperation. These values make it possible to renew and strengthen the partnerships within Kalundborg, connecting flows of energy, water, and materials, at the same time promoting the symbiotic mindset to others, on all geographical scales, from local to global.

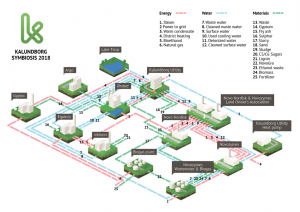

Kalundborg network diagram

Kalundborg Symbiosis is made up of 25 different streams including water, energy and material flows (see network diagram above). The resource flows emanate from six industrial and three public sector organizations. Collaboration between the partners is now second nature and every new decision in each company will consider the possibilities for and impact on the other partners and the Kalundborg as a whole. This mindset is strengthened by shared values and aided by the fact that none of the companies are in direct competition.

The partnership was formalized as a private association called ‘Kalundborg Symbiosis’ in 2011, structured as a board of directors, where each partner has a member on the board. The association has regular meetings to drive further innovation as well as other matters involving the partners. For example, the association recently decided to map all internal resource flows of the partners, and implement ten new symbiosis projects by 2025.

The beginning of the partnerships started in 1961, with the creation of a pipeline from Lake Tissø to the Equinor Refining Denmark (then ESSO) refinery. While technically not being a symbiosis project, the pipeline was a public-private partnership between Kalundborg Municipality and Equinor Refining Denmark and is still one of the key elements of Kalundborg Symbiosis today, where companies can utilize surface water instead of the more valuable and scarce groundwater resource.

Another key element, also the most visible and recognizable sign of the symbiotic cooperation, is the exchange of high-temperature steam from Ørsted’s combined heat and power plant, Asnæs Power Station, to many of the other partners in the Symbiosis. The visibility stems from the distinctive green pipes through which the steam exchange happens. The pipes can be seen running through all of the industrial areas and serve as the inspiration for Kalundborg’s logo. Additionally, this symbiotic project changed Ørsted’s business model from producing electricity with the excess steam as a by-product to steam being the primary product and comprising most of their income. This exemplifies that by having a symbiotic mindset, you can change and innovate your business model and reap both economical and environmental benefits.

The Result: every year the combined benefits for the partners are:

• Bottom-line savings of 24 million EUR

• 14 million EUR in socio-economic savings

• 635,000 tons of CO2

• 3,6 million m3 water

• 100 GWh of energy

• 87,000 tons of materials

Source: https://www.ellenmacarthurfoundation.org/case-studies/effective-industrial-symbiosis

Disclaimer

The views expressed in this publication do not necessarily reflect the views of the European Union, the participating countries and the Managing Authority.